How is Expanded Metal Made?

How is Expanded Metal Made?

What is Expanded Metal?

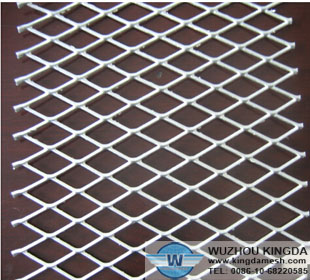

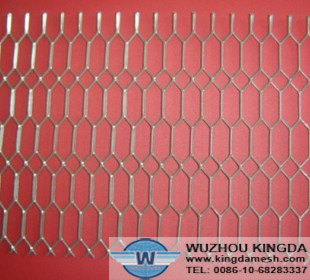

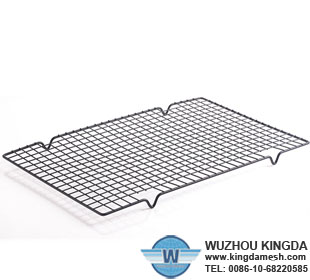

Expanded metal is the common metal grating seen in thousands of commercial and industrial applications. It can be used for protecting machinery, as floors or walls, or in many other situations. Although it looks as though expanded metal is simply metal sheeting with holes punched in it, a very ingenious and efficient method is used to expand a metal sheet into expanded metal.

The Equipment Needed

Making expanded metal requires a roller or feed for the sheet metal that is to be made into expanded metal. There must also be a cutting and expanding mechanism that is in a position to move back and forth, and up and down.

The Process of Making Expanded Metal

First, sheet metal is fed through a roller or feed below a cutting mechanism. The cutting mechanism has triangular-shaped spikes that pierce the sheet metal as well as force the hole it makes in the metal to expand. For this purpose, the spikes must be shaped like triangular pyramids. As the sheet metal is fed through, the cutting mechanism expands and cuts several holes in the metal. It moves up and down, to cut the metal, and back and forth to make alternating diamond shapes in the metal. The shapes cut in the metal can be changed, as well as the pattern in which the shapes are cut, in order to fit many needs.