How to Bend Expanded Metal

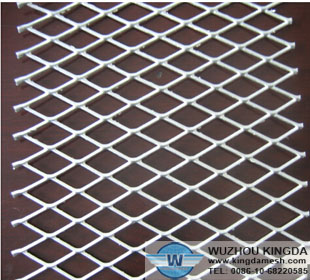

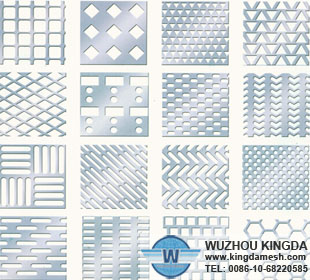

Sheet metal is slit thousands of times and then pulled to form diamond shaped expanded metal. Therefore, the same tools used to bend sheet metal are used to place a bend on expanded metal. Unlike sheet metal, it is easy to bend expanded metal without the use of sheet metal brakes or press brakes. You can place a uniform bend of a piece of expanded metal with a solid worktable at WUZHOU KINGDA, some hand tools and a little bit of time.

Instructions

1 Lay the piece of expanded metal flat on top of the worktable.

2 Stretch the tape measure across the face of the expanded sheet metal and mark the location of the bend with the paint marker. Repeat the procedure to mark the other edge of the expanded metal.

3 Align both paint marks with the edge of the worktable.

4 Place the two-by-four across the expanded metal, align it with the edge of the table and clamp the two-by-four by placing one pair of self-locking C-clamps on either side of the two-by-four.

5 Starting a one end of the expanded metal, lightly tap the metal with the wooden or rubber mallet. After each tap, move over one-half inch until you reach the other end of the expanded metal. Do not attempt to place the full bend on the expanded metal, as this will distort the bent flange.

6 Repeat the process of tapping the bend area until the flange is close to the angle that you need.

7 Release the self-locking C-clamps, remove the two-by-four and flip the expanded metal over.

8 Set the angle finder to the desired angle and place the angle finder against the bent flange. If the angle is too light, flip and secure the expanded metal as described earlier and continue tapping the metal until the angle of the bend is correct.

- Prev : A brief introduction about welded wire mesh

- Next:No Article