Perforators' essential quality For Perforated Mesh

Perforators' essential quality For Perforated Mesh.

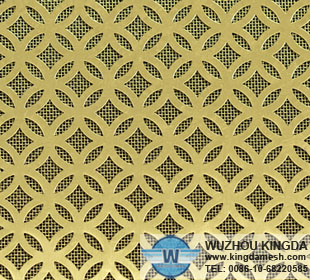

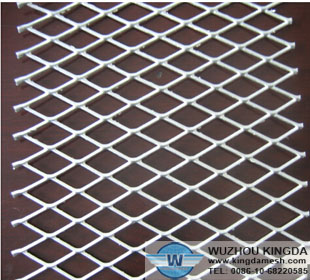

Perforators can help contractors and builders by opening the door to both new and established ways of obtaining optimal solutions for their project needs. Perforators can produce a wide range of perforation patterns, sizes and shapes in a host of various materials. These capabilities provide a broad, blank canvas for the creation of new functional and aesthetic elements that add to a building's appeal. A seasoned perforator will also provide solutions and ideas that could lead to designs that you might not have thought possible. This collaborative relationship will allow you to leverage off the perforator's experience and knowledge for improved aesthetics, increased functionality and greater cost efficiencies.

The Checklist

On the occasion that the architectural prints are unspecified for the job, it is important to consider the following before ordering Perforated Mesh. The following is an abbreviated checklist for any contractor inquiring about the perforated metal required for the job.

1. Quantity of Perforated Mesh-State the number of perforated pieces or square footage of coverage required.

2. Thickness of Perforated Mesh-Specify in gauge numbers or in decimal inches, such as 1/4-inch (6-mm) thick, 16 gauge, 0.040 inch (1 mm), etc.

3. Metal-State type of metal required: aluminum, stainless steel, copper, galvanized, etc.

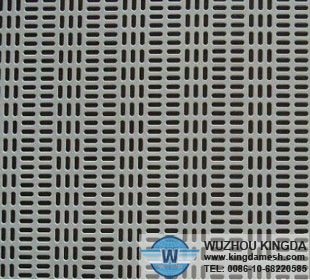

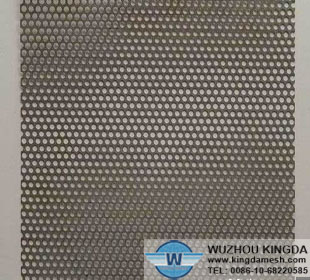

4. Perforation Size-Specify the size of perforated hole in inches, such as 0.125 inch (3 mm), 0.375 inch (9.5 mm), etc.

5. Arrangement of Perforations-Specify "staggered," "straight line" or other patterns.

6. Finish-Specify powder coating, anodizing, Kynar, plating or degreasing.

Thickness of the Material

Thin material would be appropriate for nonstructural applications or strictly for a decorative element where deflection is not going to be a problem. Thin material can also be used if the contractor needs to form in the field (following the curvature of the building). Material thickness is ultimately the responsibility of an architect or a structural engineer in factoring things such as wind load, material span and attachment methods, to name a few.

Metal Options

Wuzhou Kingda, Beijing, can perforate anything from stainless steel to copper to brass and bronze. There is no limit to the type of metal. Often times, architects want to look mainly at copper or brass for purely aesthetic purposes. But the raw material cost is so much more expensive using material like copper or brass. A similar look can be achieved with powder coating, anodizing, etc.

Another issue with material type is corrosion resistance. There are several options to minimize corrosion, beginning with the material type (stainless steel, aluminum or galvanized) and again by using powder coating, anodizing or other secondary finishes.

Interior Applications

For an interior application, regular ferrous can still be appropriate if the material needs to be protected. Galvanized and electro-galvanized offer superior corrosion resistance for carbon steel. However, when you perforate the metal, you are exposing an edge of the ferrous material and creating a potential for rust. Therefore, a second finish of paint or powder coat is still necessary.