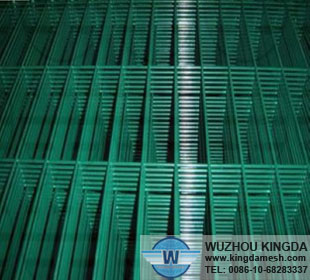

Spot Weld Wire

A spot welder creates an isolated electric arc between two movable electrodes that are attached to a stationary welding device. When a piece of metal is placed between the electrodes and they are pressed together, they pass a pre-set current through the metal, causing it to melt. Although spot-welding applications usually involve pieces of sheet metal, a spot welder can be adjusted for use on a piece of wire or wire mesh as well.

Instructions

1

Adjust the spot welder duration time, also known as amperage, to 0.1 seconds or less to minimize the heat created by the spot weld. If the transfer time is too great, the wire will burn instead of melt.

2

Adjust the welding machine to the lowest voltage setting prior to performing a test weld.

3

Test weld a piece of scrap wire or wire mesh to ensure that the settings are satisfactory for the diameter of the wire. Place the scrap wire between the electrodes and depress the actuator so the electrodes touch the test wire.

4

Adjust the welder settings if the voltage or duration is set too high or too low. If the wire melts too quickly then the voltage is set too high. If it melts too slowly, then the voltage is set too low. If the wires burn through, then the duration is set too high. However, if the wires do not fuse together at all, then the duration is set too low.

5

Once you are satisfied with the spot welder settings, weld the wire for your final product.