The Applications and Benefits of perforated metal

Applications

Interior Design, HVAC, Noise Control, Security Ceilings, Sunscreens, Building Facades, In-Fill Panels, Ceilings, Furnishings, Stair Treads and Risers, Screening and Fencing

There is an impressive variety of possibilities for the use of perforated products, which are found in nearly all branches of industry:

Food Processing: for bee hives, for grain dryers,Wine vat,And also for fish farming, hammer mill screens, silo ventilation, sorting machines (screens and drums), threshing machine screens, and for winnowing machine screens. Bent and folded perforated sheets as elements for conveyor belts.Stainless steel juice channels for wine presses.Brewing Industry - Malting Floors, Hop Screen. Food Industry - For vegetable and fruit presses

Chemical & Energy

Mechanical & Manufacturing: Automotive industry: Ventilation for tractor engine, Casing, Ventilation grid etc.

Benefits

Perforated materials have many advantages ranging from weight reduction through acoustic noise reduction to heat dissipation and much much more.

Acoustic performance helps people or workers to limit health effects from noise. Studieshave shown that perforated metals help reduce sound levels.

Studies show that having buildings use perforated metal sheets in front of their facade can bring in one study 29% energy savings (HVAC + Lighting estimated consumption in 1 year) and in the second one 45% energy savings ( heating, ventilation, air conditioning). Depending on the location of the building (intensity of the external sun), solar irradiation can be decrease by 77.9%

Perforated metal needs very limited maintenance and cleaning. This comes with a financial benefit (not having to pay a cleaning service) as long with an environment benefit of not using detergents, energy or water (drinking water from the main) for cleaning.

Perforated metal is long lasting and does not need to be replaced for years. This saves on financial costs. This enables not having to annoy occupiers of the building with work related annoyance like noise or dust. This comes with a big environmental benefit of not creating a new material sheet and its related C02 costs.

Perforated metal can be used in every location, you just need to choose the right alloy for the stainless steel.

so that it resists to seaside atmosphere or city car polluted atmosphere.

Perforated metal sheets are light which is very advantageous for the building structure when they are installed on the building.

Punching is the way most perforated sheets are created.[8] The metal removed from the sheets are recuperated and recycled to be reused for creating new sheets. Sheets of expanded metal are made in a way that does not remove any metal from the sheet.

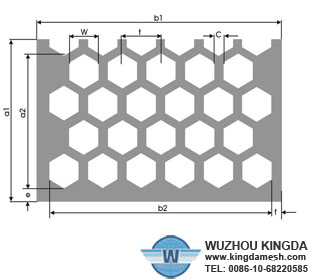

The flexibility in the design provides room for creative architectural ideas.

Perforated metal is used in the construction of bioclimatic hybrid facades.

- Prev : What is perforated metal

- Next:No Article