The Introduction of Welded Wire Fences

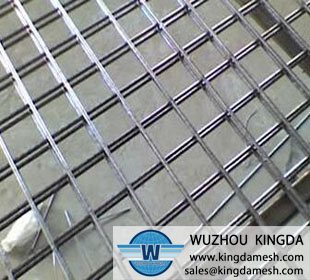

Welded wire fences Processing

It is made through the process of automation and sophisticated welding technique. The end product is level and flat, with sturdy structure and even strength throughout, the netting shows no wear and tear when cutting off a part or under a stress.

Welded Wire Fence Features

1. Precise construction

2. Uniform opening and mesh

3. Smooth mesh surface

4. Excellent corrosion

5. Rust resistance

6. Surface Treatment

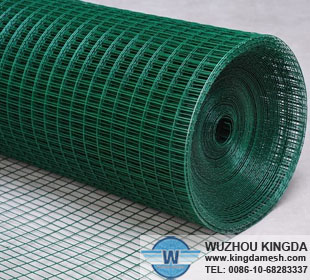

Welded wire fences materials

Good-quality material Surface treatment is commonly electro galvanizing, hot dipped zinc coating, plastic coating or vinyl coating. Hot dipped zinc coated welded mesh fence offers thicker zinc plating than electro galvanized one and stronger zinc plating adhesion, while costs a little higher. Plastic coated or vinyl coated wire fence has more colors available than galvanized welded fences.

Welded wire fences applications

Welded Wire Fences is mainly used as safety fences for roads, railway, public buildings, and the others. Its surface treatment includes PVC coated welded wire and galvanized welded wire and so on. It has more firm structure and longer service life compared with woven wire fences, due to the line welding processing.

- Prev : The way to build a gabion wall

- Next:No Article