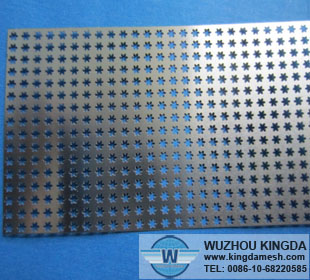

The precision of etched mesh

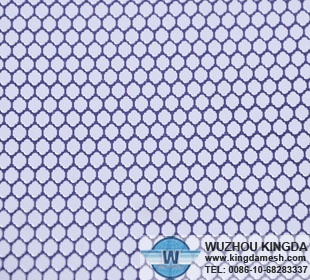

Looking for precision? Try our photo-chemically machined screens. Ultra-precise Mylar tools are produced on precision plotters using conical light sources for direct etching of a transmittal image onto the screen. Custom shapes, sizes and filters are available in metals such as nickel, stainless steel, and copper.

Etched mesh is a photolithographic technology process method for metal plate or substrate. The metal material could be processed in sheet or roll, in metallic plate or foil with various film base or glass epoxy sheet. The product pattern is copied on the metal material by the exposing machine. Then, etching it by liquid medicine. The distortion and burr will not be made by such chemical process, and the material could be kept flat. After the final washing process, the products will be very clean.

The features of etched mesh is no burrs or rough edges, no built in mechanical stresses. The base metals are consistent and unaltered. Screens and meshes are etched from solid sheets of material offering superior mechanical strength, excellent electrical conductivity, and reliable integrity of pore size regardless of flow characteristics.

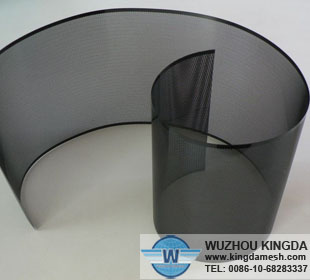

Chemically etched stainless steel screens are key parts of rotary screen applications such as fruit separators, sugar processing, micro electronics, telecommunications, optics, aviation, computers, bio metrics and medical Celerons. If you have any design and cutome-made etched mesh, welcome WUZHOUKINGDA, we can meet all your different requests.

- Prev : Types of Concrete Wire Mesh

- Next:No Article