The simple introduction of chemical etching

The chemical etching process is a tightly controlled subtractive manufacturing process that utilizes corrosive chemicals, known as etchants, to dissolve away useless portions of metal. When performed correctly, chemical etching is capable of producing highly complex, thin metal parts with very fine details and tight tolerances.

The chemical etching process begins by first thoroughly cleaning the metal to be etched by a degreaser, to ensure it is free of oils and residue, rinsed and then cleaned a second time with an acid wash to ensure the surface is free of any foreign contaminants.

The next step in the chemical etching process is to laminate the freshly cleaned metal on both sides with a UV sensitive photoresist, also referred to as a resist.

The third step in the chemical etching process is to position a phototool on each side of the coated metal sheet.

The forth step, the metal is exposed to carefully controlled ultraviolet light, which allows the selective hardening of the metal beneath the clear areas of the applied phototool.

The fifth step, the metal sheet undergoes the etching part of the chemical etching process, and is sprayed on both sides with a temperature controlled acidic etchant.

The last step of the chemical etching process is to run the etched metal through an alkaline wash and strip the remaining polymerized photoresist from the protected metal.

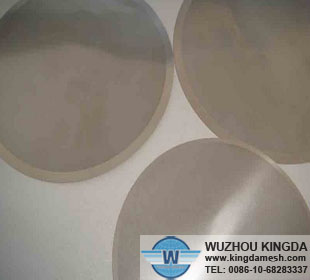

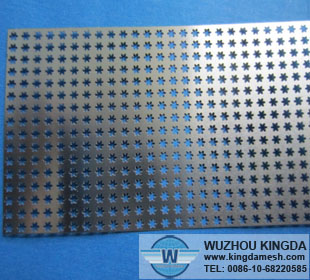

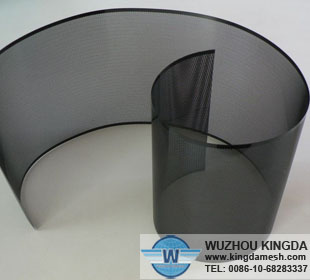

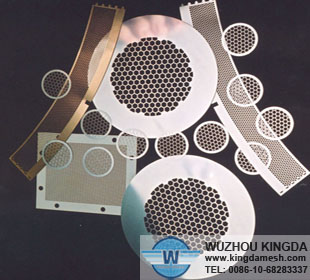

The finished product is then thoroughly cleaned, dried and inspected. And we have various chemical etching mesh can be chosen, if you are interested more, welcome WUZHOUKINGDA.

- Prev : Dust suppression net significance

- Next:No Article