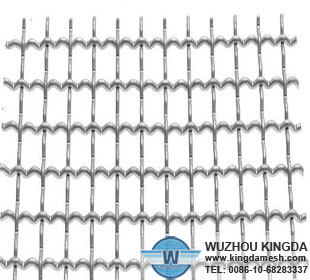

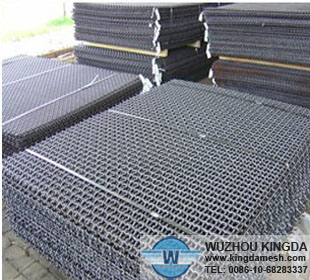

The weaving kinds of crimped mesh

We know the crimped meshes with the same materials always have different shape or surface. This phenomenon is caused by different weaving ways. And there are the weaving kinds of crimped mesh.

1. The first one is double weave. This weave is commonly used for screening operations in smaller openings. Used for medium to heavy wire in relation to screen opening size.

2. The second one is scalping weave. It is also known as Lock-Crimp due to the deep crimps which lock the wires in place. For light to medium wire in relation to screen opening size.

3. The third one is double lock crimp. Single shoot oblong openings solve minor blinding problems for better flow.

4. The fourth one is flat-top. Improves material flow with a much smoother, flatter surface than other weaves. Lock weave provides a longer wear life and maintains accurate openings.

5. The fifth one is triple shoot. Long openings will keep sticky or wet material flowing freely. Weave holds wires securely yet permits slight vibration to keep openings clear.

6. The sixth one is intermediate crimp. When open area is important. Extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.

All in all, there are the six kinds of weaving of crimped mesh. Hope they can help you.

- Prev : How is Expanded Metal Made

- Next:No Article