What Is Zinc Coated Wire?

What Is Zinc Coated Wire?

Metal wires are used to bear mechanical loads and carry electricity and signals, among other uses. They are produced by drawing a metal through an opening known as a draw plate. Wire gauge is the general term used to define different sizes of standard wire thicknesses. Coating the wires with zinc is a popular practice to avoid rusting, which causes wires to become brittle.

Rusting: A Major Disadvantage in Iron Wires

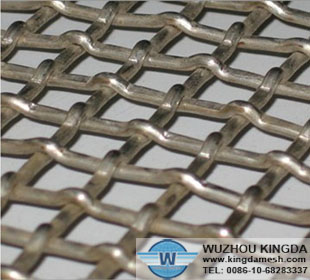

Iron and carbon steel wires are used mainly in making wire meshes and structures of different shapes and sizes. Owing to the elasticity and strength of steel, it can be drawn into different wire patterns with ease. But iron and carbon steel wires are vulnerable to rusting. Rusting is a natural process whereby iron and other metals are slowly turned into oxides in the presence of air and moisture, resulting in the weakening of the metal.

Use of Zinc Coating to Prevent Corrosion

Using products made from iron wires can be dangerous in high-moisture environments as the wires will lose their strength quickly and become brittle. The most effective way of checking this is by coating the metal wire with another layer of sacrificial metal so the damage is confined to the outer layer. When zinc is used to cover iron or steel wires to protect it from corrosion, such a setup is called zinc-coated wire.

Reason behind Zinc Coating of Metal

Zinc is the fourth most available metal in the world. By nature, zinc is more reactive to the environment. As a result, it attracts most of the air and moisture to itself to form zinc oxide and zinc hydroxide. Upon reacting with the carbon dioxide present in the air, this compound converts into zinc carbonate--a strong and impermeable substance that does not allow more moisture or air to interact with its underlying layers.

Effects of Zinc Coating on Wires

As a result of the reactive tendency of zinc, the bottom layers of iron or carbon steel remain clean and free from rust for a long time. Industrially, zinc coating is done after the wire is drawn from the die and then hardened. For the coating process, the wires are dipped into molten zinc before being taken out to cool. This gives the wire excellent elasticity.

Uses of Zinc-Coated Wires

The layer of zinc coating can vary between 100 grams per square meter to 300 g/m2, just as the weight of a single coil of galvanized wire package can vary from 10 kilograms up to 1,000 kilograms. These zinc-plated iron wires are used to tie vines in vineyards and plants in orchards. These wires support plants and provide durability under stressful conditions. They are also used for building cages for birds and small pets.