About the chemical etching technique

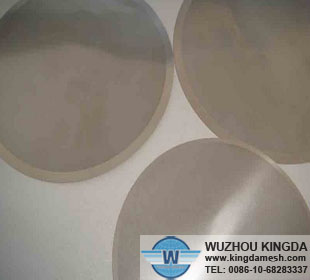

The chemical etching is the process for speaker grilles, filters, building decorations, metal sheets, screens, meshes, separators, lighting diffusers and some perforated applications.

The chemical etching process produces perforated metal parts with consistent, burr-free holes as small as 0.3mm thick material. As a general rule, minimum hole size is equal or bigger than the thickness, e.g. if by 0.3mm material, then the smallest hole should be 0.3mm or 0.4mm.

Unlike the perforating methods such as punching, stamping or laser cutting, the chemical etching of metal leaves the material free of burrs and induced mechanical or thermal stress or deformation.

And the main application of the chemical etching screen is filtration and decoration.

1. Applications range from heavy gauge metal effluent filtration to extremely fine thin-gauge filters and diaphragms for liquids and gasses in a variety of alloys including steel, copper, aluminum, nickel and molybdenum.

2. Metal meshes can be chemically etched in a wide variety of alloys including stainless steel, low carbon steel, aluminum and so on. Holes can be made in a variety of shapes and sizes at no additional cost in tooling. Precision etched meshes, grids, filters and screens are used in many types of industrial, decorative and architectural applications. In many cases, chemical etching of metal meshes, grids, screens and filters provide better value and performance than woven or punched products.

If you have more interests about the chemical etching, please feel free contact WUZHOUKINGDA. We have a lot of range and shape for your choosing.

- Prev : The important of a cooling rack

- Next:No Article