Carbondale manufacturer helping build One World Trade Center

Aluminum plates crafted by a Carbondale specialty manufacturer will become part of the exterior of the new One World Trade Center in Manhattan.

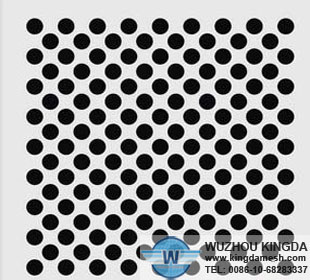

Quality Perforating Inc. is manufacturing 175,000 square feet of pierced aluminum panels that will wrap the lower levels of the main structure at the site of the terrorist attacks of Sept. 11, 2001.

"I think, now, we have really drawn attention," company President Bob Farber said as he sat in an office at QPI's 80,000-square-foot plant on Dundaff Street.

"The whole envelope of the base of the building is wrapped in this," company Vice President Mike Gilboy said as he pointed to a small stack of 16-foot, 68-pound perforated aluminum panels destined for the exterior of the 104-story, 1,776-foot skyscraper.

Mr. Farber, an electrical engineer from Carbondale, and other investors in 2001 bought the bankrupt Laubeck Corp. perforating plant that had traced its origins to Cross Engineering Co. at the same location in the late 1800s. Perforators pierce metals and other materials for industrial, architectural, household and artistic applications.

"We make all our own tool sets," Mr. Farber said. "We are the fastest-growing, most technologically oriented perforator in the country."

QPI came to the One World Trade Center project through a an Italian engineering contractor with a manufacturing plant in Connecticut that received a $40 million order for the metal curtain wall on the skyscraper's lower section. QPI's 3,600 perforated panels surrounding the bottom 20 stories of the structure will be adorned by exterior, stainless-steel-clad aluminum louvers.

QPI's plates will enclose the building's mechanical area for heating, cooling and electrical functions and will allow natural light and airflow into the structure, Mr. Gilboy said.

QPI's achievement traces a long history of industrial accomplishment in Carbondale dating back more than 180 years. In 1829, the Delaware & Hudson Canal Co. established the Gravity Railroad just blocks away from QPI's plant. The D&H system for anthracite coal transportation employed a series of inclined planes and steam engines preceding the development of steam railroad locomotives.

QPI makes products for hundreds of other uses, from light fixtures, furniture and mining screens to stereo speakers and ceiling panels.

"We make parts for every industry," Mr. Farber said. "We made all the garbage cans at Yankee Stadium."