Crimped Wire Mesh Specification

Crimped Wire Mesh Specification

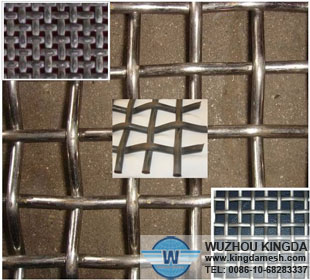

Crimped Wire Mesh is a product made up of pre-formed wire strands, interwoven in a variety of patterns to create a sheet with regularly-spaced and shaped openings of various sizes. In contrast to other Crimped Wire Mesh products, the individual strands making up the weft and warp planes of Crimped Wire Mesh are crimped to form regularly-spaced kinks made to coincide with the points at which the waft and warp strands cross each other, meaning that one strand lies securely in the kink of the other. This makes for a stable mesh that maintains its strand spacing well when flexed, and is also flatter than other types making it ideal for use as filters, industrial barriers, and barbeque grills. Several grades of wire are used to produce Crimped Wire Mesh and may be coated or galvanized to prevent corrosion.

Wire mesh is a widely-used product in a variety of industrial, manufacturing, and domestic applications that is made of wire strands woven together to form a net. Crimped Wire Mesh is one of the more common types, popular due to its stability and flat profile. These characteristics are a result of a unique, pre-forming process that involves crimping a series of evenly-spaced depressions, or kinks, into each strand of wire making up the mesh. The kinks are spaced in such a way that the individual strands of the weft and warp planes, these being all the strands laid in one direction and all those laid at right angles to them, lie in the kinks at the points at which they cross each other. This lends the mesh strength and stability, as the strands are less inclined to slide across one another when the mesh is flexed, and also makes the sheet flatter.

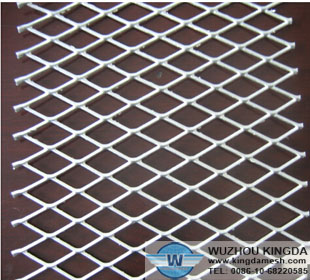

There are several weaving patterns used to produce Crimped Wire Mesh, including plain weave, twill weave, and plain or twill Dutch-weave patterns. Plain weave mesh is the most common and sees the warp wires pass alternately above and below the weft wires in contrast to where the weft wire passes alternately over and under two warp wires, such as in twill weaves. Each pattern imparts specific characteristics in the mesh that may further be enhanced by the use of different wire gauges and types. These include hot-dipped galvanized, copper, or stainless steel wire types that protect the mesh from corrosion. Some Crimped Wire Mesh products also feature wire that is plastic-coated after crimping to form a smooth, corrosion-resistant product.

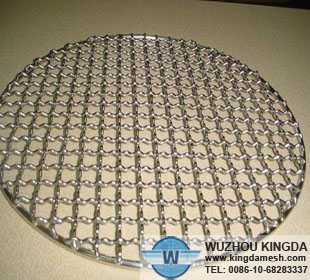

There are many common uses for Crimped Wire Mesh in a wide variety of industries. These include industrial barriers, reinforcing, and filters. One of the best-known domestic uses of these mesh products are the stainless steel mesh sheets used as barbeque grills.