The expanded metal process

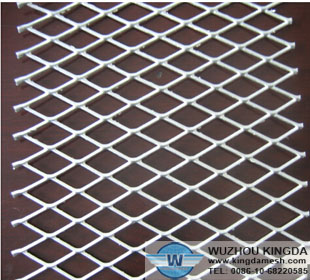

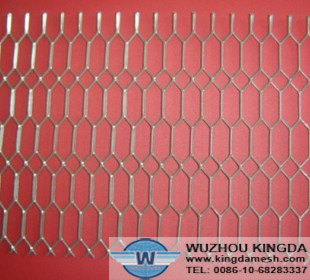

Expanded metal is made by a process of slit and stretch. A precision die slits and stretches the material in a single operation. The material is then processed through a set of rollers which adjusts the final thickness. The shape, form and number of openings are dictated by the particular tool used (See Die Chart for discussion on available dies).

The Tool selected dictates the Long Way of the Diamond (LWD), whereas the strand width and the Short Way of the Diamond (SWD) is machine adjustable and is selected based on the needs of the customer.

WUZHOUKINGDA expanded metal is used in batteries, electronics, aerospace, aircraft, medical, packaging, filters, fuel cells, heating elements, resistors, load banks, food & drug products, automotive and wherever mesh and perforated foils, metals with high precision characteristics are required. Metals we regularly produce include: aluminum, brass, copper, steel, stainless steel, and zinc.

Expanded metal is light and fantastically flexible. It can be bent, shaped and laminated with a variety of flexible materials. A square foot of raw material when expanded can produce two to three times or more of open area material without scrap. Stamping or etching creates open area by removing material that becomes scrap resulting in higher material costs.

- Prev : About the chemical etching technique

- Next:No Article